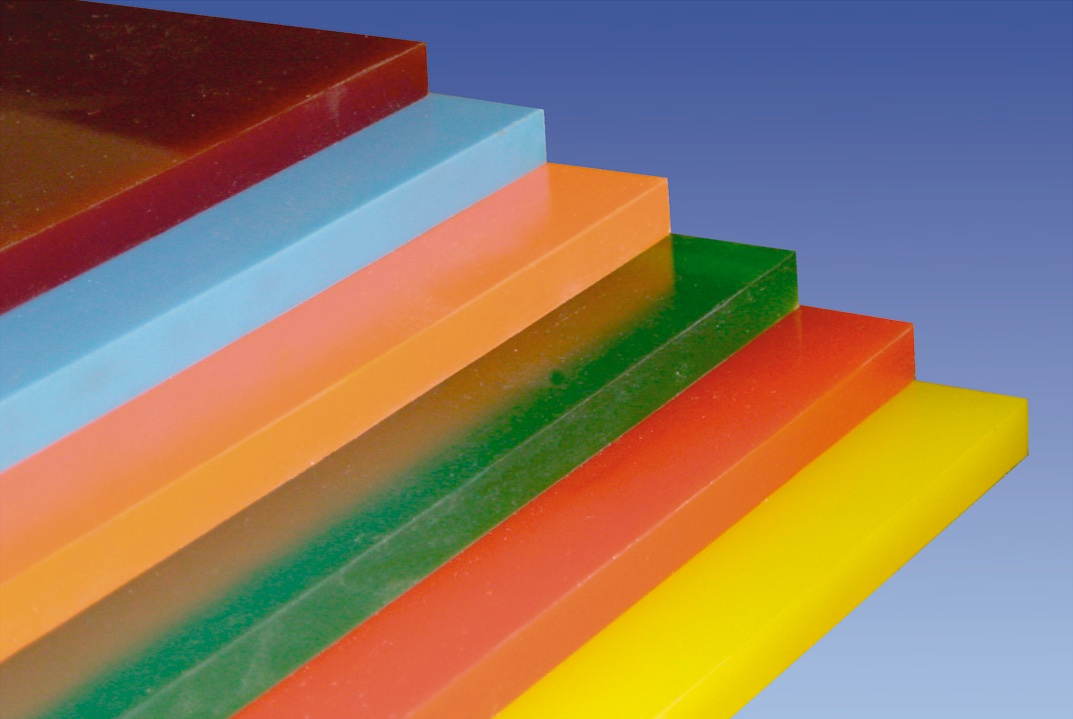

Wear-resistant polyurethane plate

WearProtect PU

Polyurethane (PU) is a hard material that is also very slippery. It has good sliding properties. That is why we often apply PU sheets for lining hoppers, silos and worm screw trays. Actually anywhere where wet and more or less sticky mass flows along or through. The properties of PU wear plates are midway between rubber wear plates and polyethylene (PE) plates. Polyurethane is less slippery than PE, but more abrasion resistant. At the same time, it is smoother and harder than rubber, more resistant to high-pressure spray cleaning and also resistant to oils that attack rubber.

Applications wear resistant polyurethane plate

These properties make polyurethane suitable as an alternative to rubber in the concrete industry. There, after cleaning chutes and mixing cubes, they often use oil to protect steel parts from rusting. In those places, it is better to replace the rubber of sealing strips, among others, with PU strips. We further encounter PU wear plates on mixing vanes, as lining of transport chutes, as scrapers on conveyor belts, in worm conveyors and all kinds of chutes. We also use PU wear plates with a special food mark in bunkers for the (animal) food industry. By the way, PU is not suitable for processes with media above 80˚C. So it is in concrete production, but not in the asphalt industry.

Highlights

abrasion-resistant PU sheets

- wear-resistant with good sliding properties

- coating, sealing and spraying

- ideal for sticky products

- application up to 80˚C

- mixing vanes, bunkers, closing valves transport chutes, wipers and scrapers

- also customization and assembly

PU wear resistant sheets or spraying

The picture shows an application of the slide plates in the standing time improvement. Here we fixed the PU plates with a bolt connection. In other applications, we can also glue them in place. In addition, it is possible to coat irregularly shaped parts with PU using a special spray technique. To do this, however, the part must be dismountable for transport, as we cannot deliver sufficient quality on site. By the way, the two-component PU repair paste deserves special mention.

Technical details PU sheets

We sell our wear-resistant polyurethane sheet (Wivé WearProtect PU) in standard sizes of 2000×1000 mm with a thickness of 1 to 40mm, with or without a backing of expanded metal, jute or lochblech. The hardness of the PU wear plates is between 60 and 90 Shore. Based on the specific application, we can advise on the right choice.

”

Now that we have replaced the rubber seal with PU sheets, we can lós with the high-pressure sprayer.

More information about wear resistant PU plate

Abrasion-resistant polyurethane seems well on its way to replacing natural rubber, except in applications where impact and noise damping is more important than wear protection. In principle, we have no preference for rubber or PU. For us, only the result counts. Our products and techniques find their applications in a wide variety of industries. Wherever wear and tear occurs, Wivé Techniek can contribute to wear protection and thus extend service life. Also in your processes? Definitely. Contact us for an introduction to our wear protection experts, or request a quote right away!