Van Werven wants to reuse plastic 100%

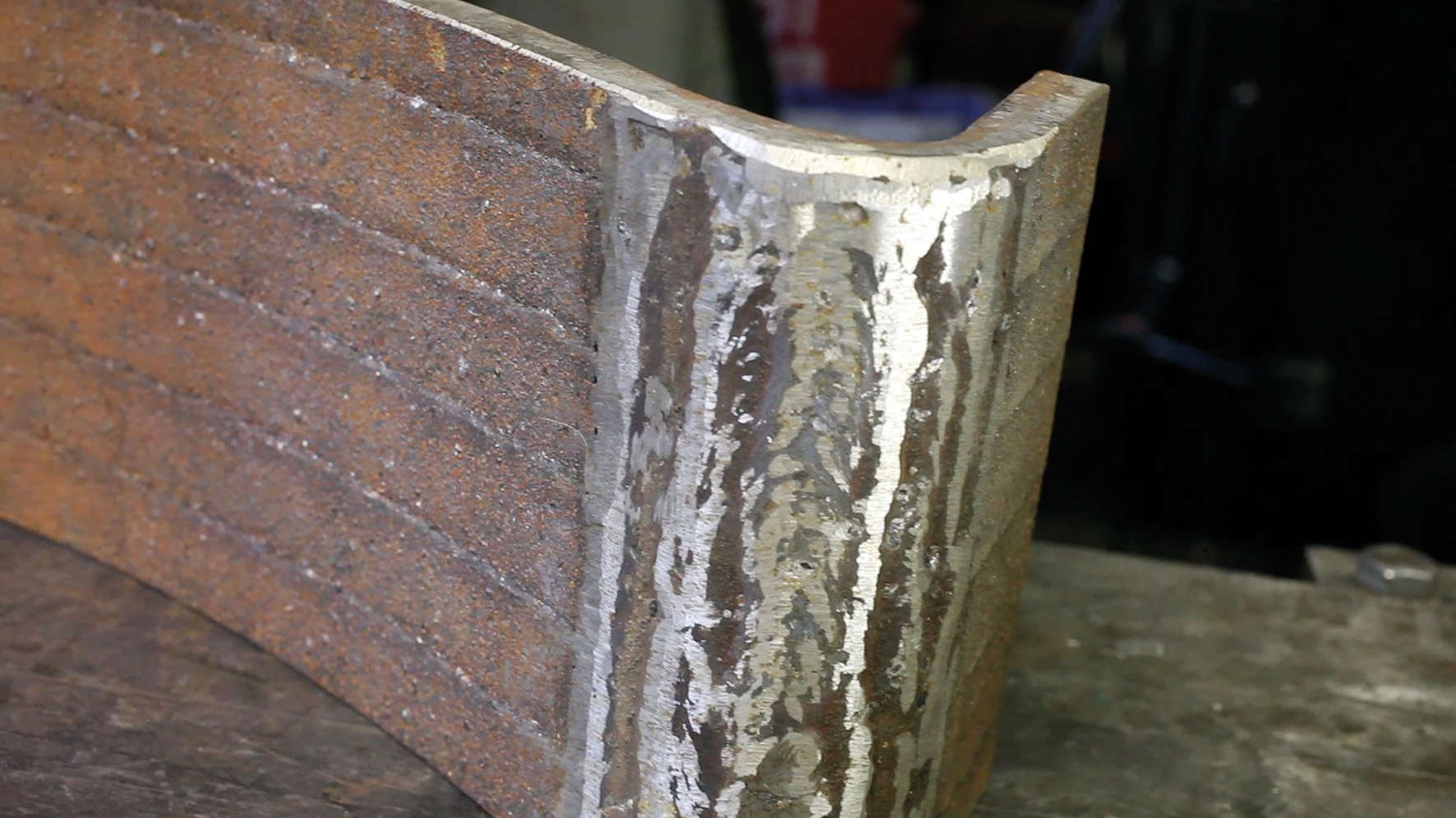

The shredding and grinding of plastic releases enormous forces.

Van Werven is a company in infrastructure and recycling. A real family business, started 70 years ago in Oldebroek and now with 500 employees. Remarkably, many family members still work there, including ten fathers with sons, one father with daughter and nineteen brothers and sisters. There are even three generations of the Van Werven family in the company!

Common thread in the company’s history is innovation. ‘Can’t be done’ does not exist at Van Werven, which constantly develops new processes, machines and markets. A young and successful business unit is plastic recycling. We talk about this with Jan van Oostenbrugge, facility project manager and technical specialist.

‘From that first wood-powered factory, we have continued to innovate’

“We once started with a conveyor belt and some boxes, with which we could sort plastic by type. Just to see ‘what can we do with it’. Legislation was then in the making around waste disposal at licensed companies, AND the borders for disposal to Germany were closing, so a huge market was emerging. From that first woodchip factory, we continued to innovate. At the time, we thought that perhaps a capacity of 15,000 tons per day would be feasible. Now we are doing 65,000 tons in the Netherlands alone and are busy setting up plants in England, Germany, Belgium and Poland, among others.

Sorting, washing and grading

‘Plastic’ sounds like a homogeneous product but it is definitely not. Eighty percent of what we receive comes from the landfill. Bottles, vials, packaging, children’s toys – from cars to slides -, buckets, grout tubs … you name it. That consists of PVC, polypropylene, polyethylene, hc, low density polyethylene, among others, all together some 45 different types.

”

From that first woodcraft factory, we have continued to innovate further and further

All these materials arrive at our sorting line, where we sort them partly manually. Then the various materials are pre-shredded and removed from soap residue, oil and grease, sand and other contamination in the washing drum. Finally, the clean plastic is ground into granules, shreds or even dust, as fine as flour.

Purest possible product as raw material

In sorting, we use zinc/drift techniques and infrared light, among other things, and we recently put into operation a color separator. Our aim is to leave as clean a material as possible at the end of the process. Previously, our material was mainly used as an intermediate layer, or for products where quality is less important. But now we achieve about 98% purity. Good enough as a raw material for new products.

‘By now we achieve about 98% purity, good enough as raw material for new products’

The Wavin, for example, makes new PVC pipes with our raw material. This is financially attractive because our ‘second-hand’ material costs half as much as new plastic from the petrochemical industry. So companies who buy our raw material can not only tell their customer that they are using recycled material, they are cheaper too!

Separation at the source is profitable

The effort we make to separate everything as best we can also shows how important it is to sort properly at the source. If you take residual waste to the landfill, you pay over €130 per ton to get rid of it. If you deliver ‘clean’ plastic to us, you get money!

6/24 run through the chain

We are in the middle of a chain with our combination of waste processing and plastics production. We work six days a week 24 hours a day. At the entrance push the suppliers, the collection companies who have to dispose of their plastic waste day in and day out. At the exit pull the producers, who depend on the supply of raw material. So we can’t afford to go out of production. And that’s where our cooperation with Wivé Techniek comes in handy. We design our own machines and have been cooperating with Wivé in this for about six years. They help us extend the service life of machines by preserving certain wear-sensitive parts.

”

With the help of Wivé, we were able to increase the tool life by a factor of 4 to 6

Fighting together against wear and tear

You don’t realize it, but shredding and grinding plastic releases enormous forces. Just imagine if a waterworks company arrived with a trailer full of rejected rigid PVC pipes, with diameters ranging from 50 to 500 mm. Try getting that small.

‘With the help of Wivé, we were able to increase the tool life by a factor of 4 to 6’

We have special “shredders” that shred, crush, grind the material. The parts that come into contact with the plastic wear out very quickly, so we had to stop all the time to replace them. With the help of Wivé, we were able to increase the tool life by a factor of 4 to 6. So instead of stopping for maintenance once every four weeks, the machine now only needs to be stopped once every 16 weeks.

In recent years, we have improved all existing machines with the materials from Wivé Techniek. And nowadays, when we devise new machines for transporting or processing plastics, we consult with Wivé’s wear specialists at an early stage. So we go for optimal application of wear reducing measures from the beginning.